To demagnetize a transducer’s magnetic core, the following steps are typically used:

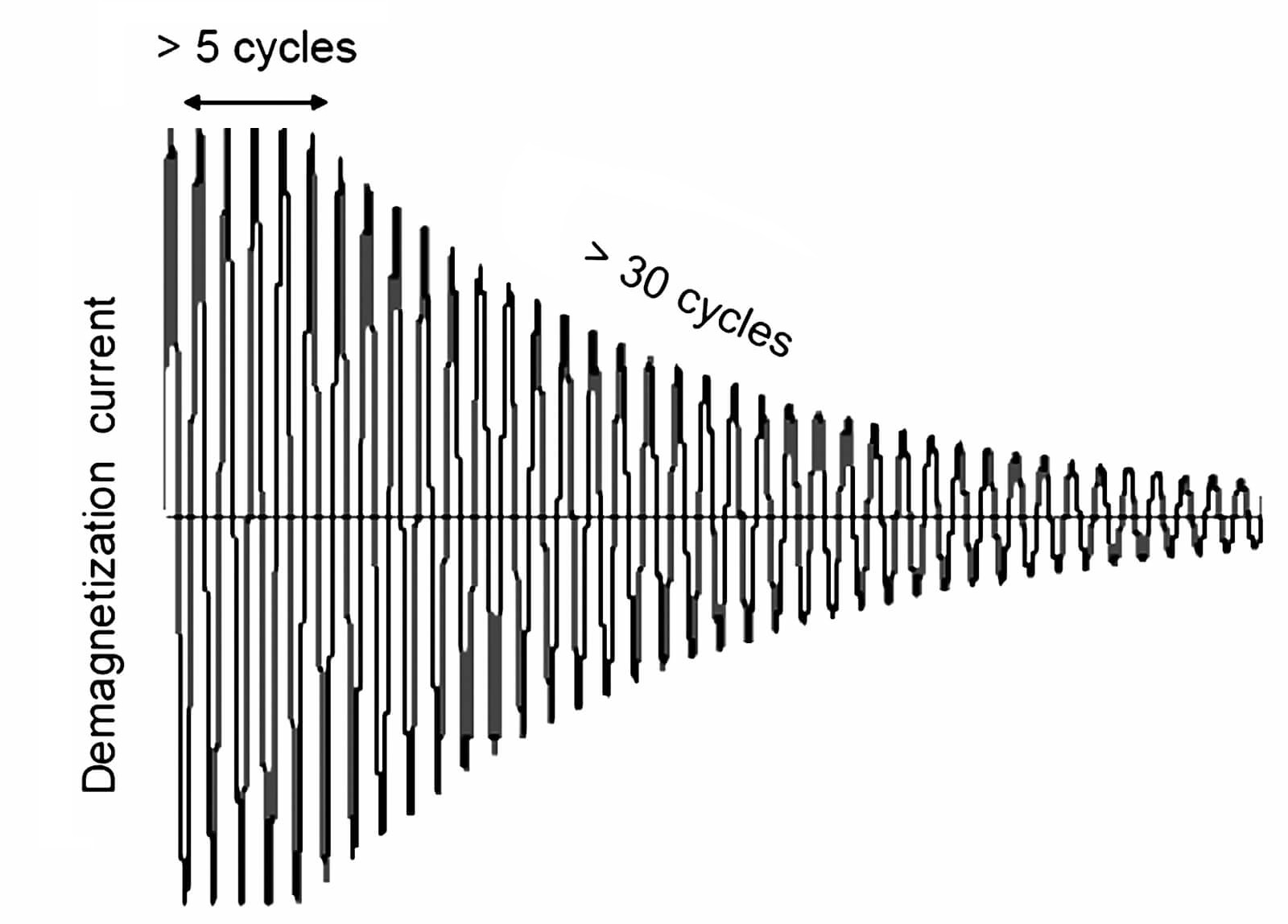

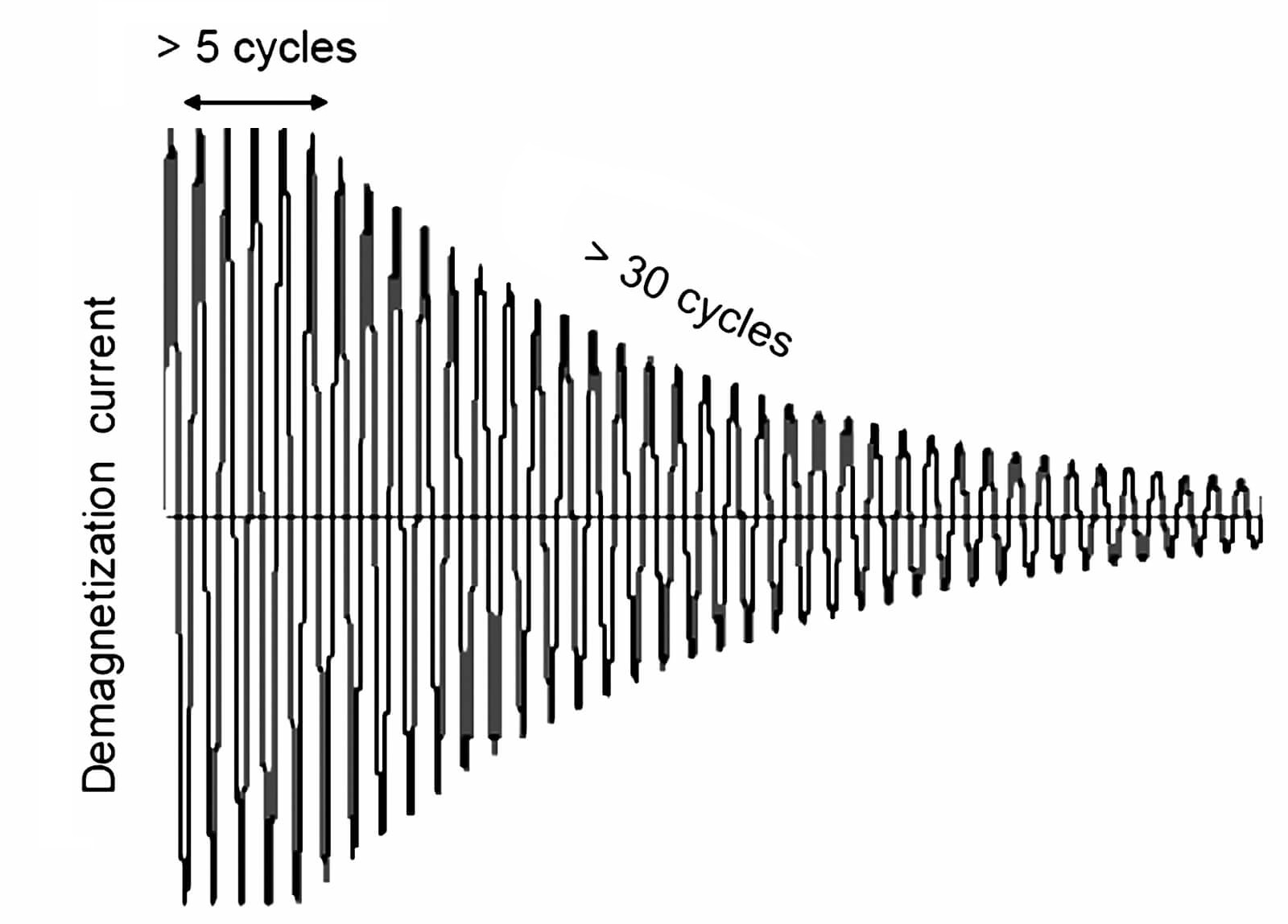

1.AC Excitation: A low-frequency AC source drives the magnetic core through its entire B-H hysteresis loop (the magnetic field vs. magnetization curve), applying alternating current to cycle the core’s magnetization from positive to negative saturation.

2.Gradual Decrease of Excitation: After cycling the core through the B-H loop for at least 5 full cycles at maximum amplitude, the amplitude of the AC excitation is reduced gradually. The rate of reduction should be no faster than 4% per cycle to ensure a smooth return of the core’s magnetization to zero (the origin of the B-H curve).

3.Time Requirements: Typically, a demagnetization cycle will require around 30 cycles at a low frequency, such as 500 milliseconds at 60 Hz.

For closed-loop transducers (devices that have a compensation coil), additional care is needed because the compensation coil can interfere with the demagnetization process by negating its effects. This interference can prevent the core from reaching its neutral state. Therefore, extra steps may be required to ensure proper demagnetization.

Alternatively, partial demagnetization can be achieved by applying a specific signal of opposite polarity to the core’s magnetization. However, this method is more complex because it requires precisely determining the correct amplitude and duration of the signal to effectively reduce the magnetization without overshooting or undercompensating.

In practice, if a specific application is well understood, it is possible to determine the necessary correction signal empirically and apply this whenever demagnetization is needed.

Demagnetization is essential for maintaining the accuracy and reliability of a transducer’s measurements, especially after strong magnetic influences or long-term use.

Copyright © 2024 PowerUC Electronics Co.