Let’s take a product with a supply voltage of +5V and an output of 2.5V ± 0.625V with a precision of 1% as an example.

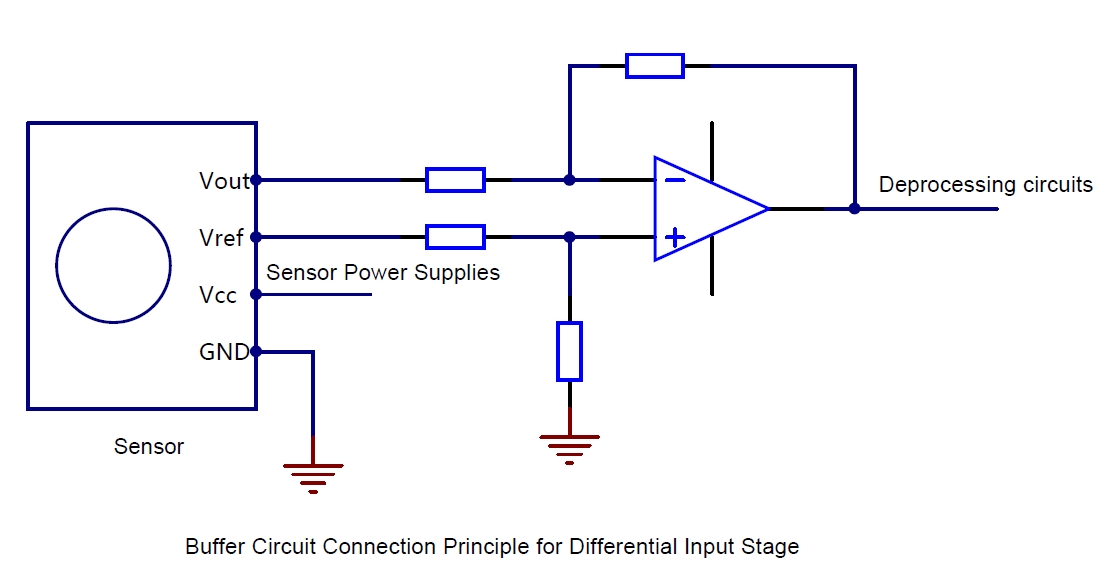

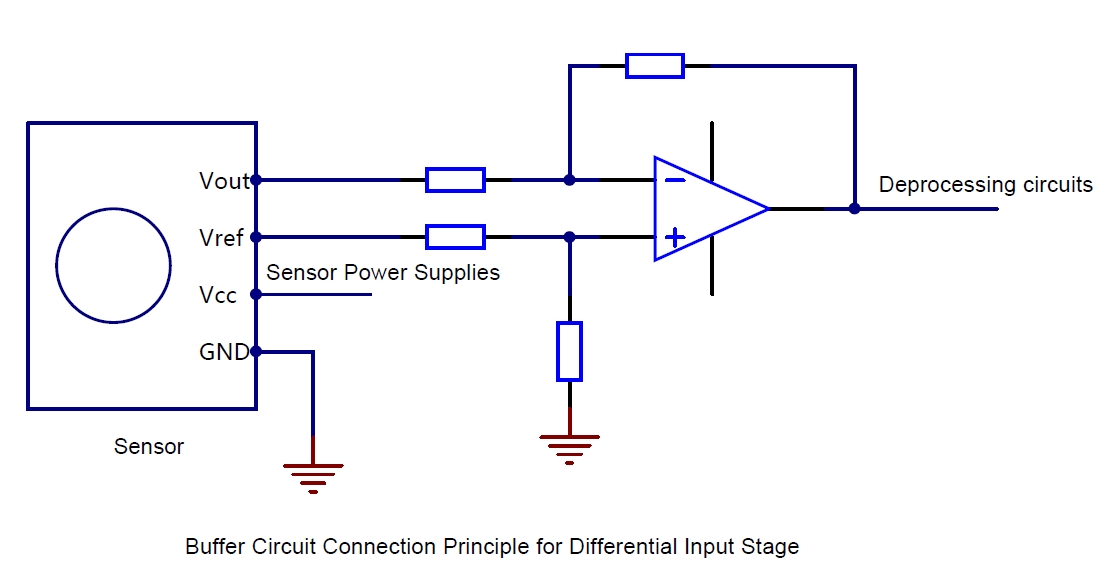

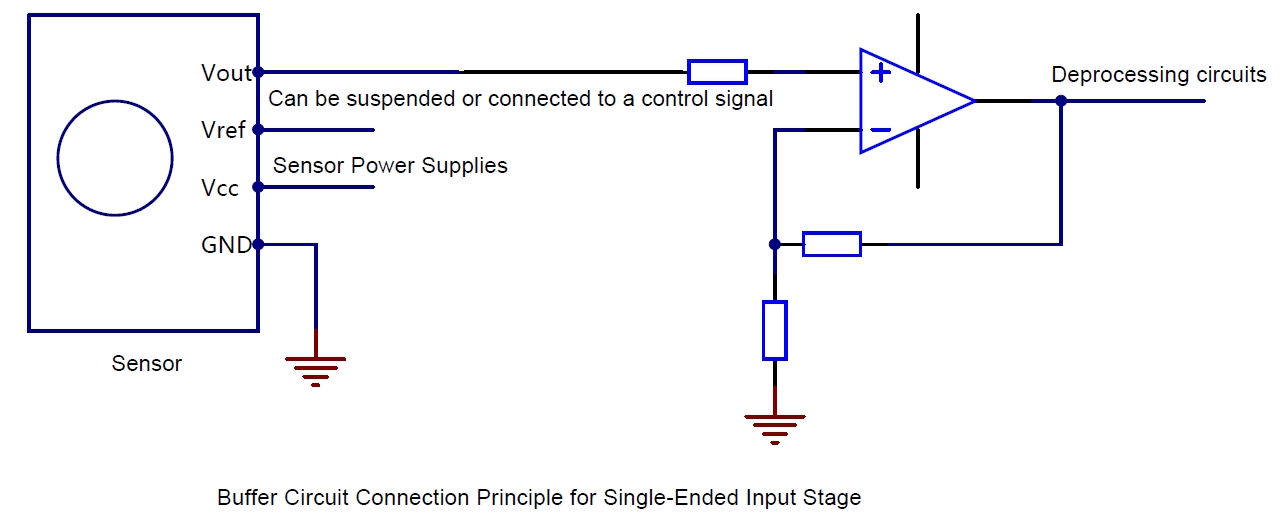

Our Vref pin serves two functions: one is to act as a reference point for output, commonly used in differential input acquisition devices; the other function is for single-ended input acquisition devices, where it is used to control the sensor output, making the static output (2.5V) more accurate. It only affects the static output (2.5V when there is auxiliary power and no input signal) and does not affect the amplification (0.625V).

Due to the discreteness of product parameters, sensors cannot be perfectly identical and ideal, and there will always be some degree of error. For most of our products, the static reference point error is within ±15mV. This means the static output of 2.5V (with 0V or GND as the reference point) will be between 2.485V and 2.515V, which is considered within the acceptable range.

For example, for a product with a power supply of +5V and an output of 2.5V ± 0.625V with a precision of 1%:

If the output is referenced to 0V (GND), we calibrate it as follows:

First, check if the Vref voltage meets the requirements (standard is 2.5V ± 1%, generally no more than 0.5%).

The second step is to adjust the static output to between 2.485V and 2.515V (i.e., 2.5V ± 15mV).

The third step is to apply the input signal to the rated input and adjust the output to within 2.5V + (0.625V ± 1%).

Finally, check if the output at 10% of the rated input is accurate. If there is significant error, adjust the zero-point component for correction. Then, check if the zero-point and full-scale values meet the requirements. If everything is correct, the product moves on to the next process step.

If the output is referenced to Vref, we adjust it as follows:

First, check if the Vref voltage meets the requirements (standard is 2.5V ± 1%, generally no more than 0.5%).

The second step is to adjust the static output to between 2.485V and 2.515V (i.e., 2.5V ± 15mV).

The third step is to connect the black probe of the multimeter to the Vref point, apply the input signal to the rated input, and adjust the output to within 0.625V ± 1%.

Finally, check if the output at 10% of the rated input is accurate. If there is significant error, adjust the zero-point component for correction. Then, check if the zero-point and full-scale values meet the requirements. If everything is correct, the product moves on to the next process step.

If a product adjusted using the first method is used in a differential input acquisition device, the acquired signal will be inaccurate and may even produce negative output errors.

If a product adjusted using the second method is used in a single-ended input acquisition device, the acquired signal will also be incorrect and may result in overflow errors.

By default, our products are calibrated using the first method (referenced to 0V/GND), as most customers request this.

Example 1: A product calibrated using the first method, with Vref = 2.510V and Vout = 2.505V in the static state. This product is qualified, and the precision is acceptable. However, when used in a differential input acquisition device, since Vout is lower than Vref, the static output will be negative, which is incorrect.

Example 2: A product calibrated using the second method, with Vref = 2.510V and Vout = 2.520V in the static state. This product is also qualified, as the zero-point error does not exceed 15mV. However, when used in a single-ended input acquisition device, the output of 2.520V exceeds the calibrated 15mV error, and the full-scale value will also be higher, which could reach up to 2% in extreme cases, affecting the customer’s use.

Now that some customers have reported this type of error, we are asking them to provide calibration requirements to correct the issue. Sales representatives are also being asked to label products based on different calibration methods to ensure correct production for customers.

Copyright © 2024 PowerUC Electronics Co.